The technological race for longer-lasting, lighter and safer batteries has been driving the electric mobility industry for years. Ever since the first electric cars began to take off, the industry has focused its efforts on solving a key problem: the limited range imposed by the graphite in the anodes of lithium-ion batteries. This material, standard for decades, has been a technological ceiling that researchers around the world have been trying to overcome for some time.

Alternatives such as silicon, capable of storing much more energy, or sodium, which is cheaper and more abundant, have been making headway. With varying degrees of success, they have all paved the way for a new generation of accumulators that promises to radically break the current barriers and bring electric vehicles closer to the range of combustion engines.

Solid-state batteries: the revolution that is already underway

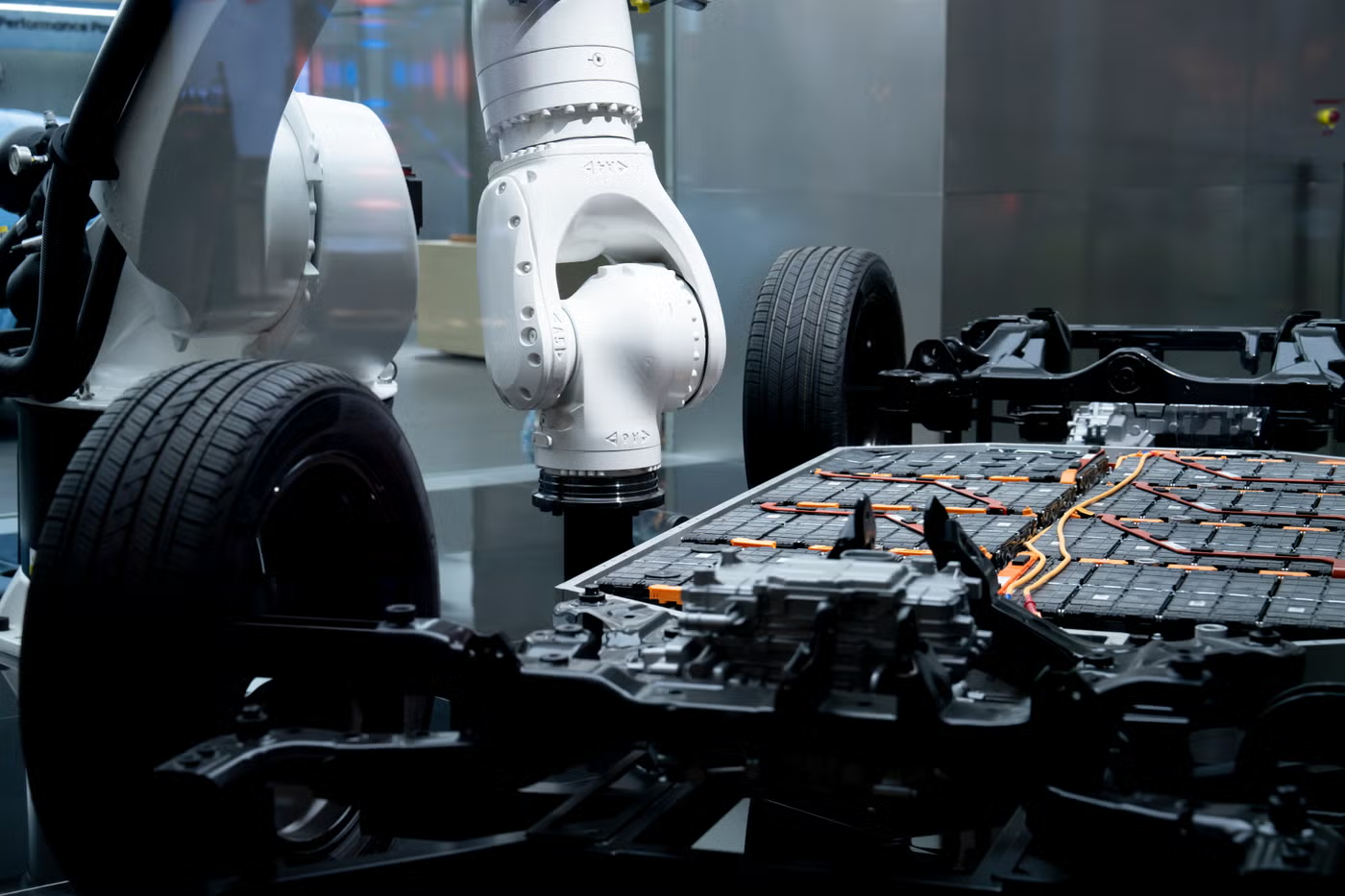

Among the most decisive advances, solid-state batteries (SSB) stand out as one of the most promising technologies of recent decades. Their fundamental difference lies in the replacement of the liquid electrolyte, which is flammable and susceptible to thermal leakage, with a solid electrolyte, which is much more stable, safer and more energy dense.

Japanese manufacturer Toyota is one of the companies that has gained the most ground in this race. The brand continues to advance towards a commercial prototype capable of breaking all durability and autonomy records. According to the company, its new batteries will retain up to 90% of their capacity after 40 years of operation, a fourfold increase over the service life of current batteries.

This would be a paradigm shift: the same battery could be reused in several vehicles over decades, reducing waste, emissions associated with mineral extraction and long-term costs. In environmental terms, purchasing a SSB would be equivalent to replacing up to four conventional batteries.

In addition to their durability, these batteries promise more than 1,000 kilometers of autonomy per charge, along with minimum recharge times, two of the factors that most condition the acceptance of electric vehicles among consumers.

A global race to master the energy of tomorrow

While Toyota accelerates, Asia continues to set the pace. CATL, BYD, South Korea and China are competing to produce batteries that can be charged in minutes and travel thousands of kilometers. On the other side of the ocean, Tesla is working to regain a leading role in a technological battle that could redefine mobility in the 21st century.

Competition between the United States, China, Korea and Japan is driving an unprecedented revolution: safer, longer-lasting and more efficient batteries, capable of definitively erasing the differences between electric and combustion cars. What once seemed like science fiction is already being tested in laboratories, pilot plants and on the road.

Toyota sets date for final leap

Toyota plans to start commercial production of its solid-state batteries between 2027 and 2028. It will start with luxury models, such as Lexus and Century, before being extended to more popular vehicles such as the future Toyota Corolla.

The breakthrough, according to Interesting Engineering, is the result of a long collaboration with Sumitomo Metal Mining, a company with which it has developed highly durable cathode materials using a patented process. The project has been declared strategic by Japan, which will invest part of a $7 billion national plan to strengthen its technological independence vis-à-vis China and South Korea.

In addition, the Idemitsu Kosan refinery is already building a plant capable of producing 1,000 metric tons per year of lithium sulfide, a key material for these batteries. This would make the supply chain completely local, lowering costs and ensuring stability in production.

A promising future, but with challenges

Although BSSs represent a giant leap forward, experts warn that mass adoption will take time. Initial costs are very high and manufacturing processes are extremely complex. Even so, Toyota is confident that their durability, safety and efficiency will compensate for the investment.

If the forecasts come true, this new technology will not only drive the electric cars of the future, but will also mark a turning point in the global energy model, reducing waste, dependence on raw materials and emissions.